Exploring Why Race Alignments and Corner Balancing Are So Expensive

Some people like getting down and dirty working on their cars. I prefer being organized, methodical, and thorough rather than rushing to get something done quickly. That's probably why I like setting up my car myself.

While corner balancing my car might only take an hour, the entire process can take me a week or more. Why? Well, I break it into parts, and the setting up takes longer than the setup!

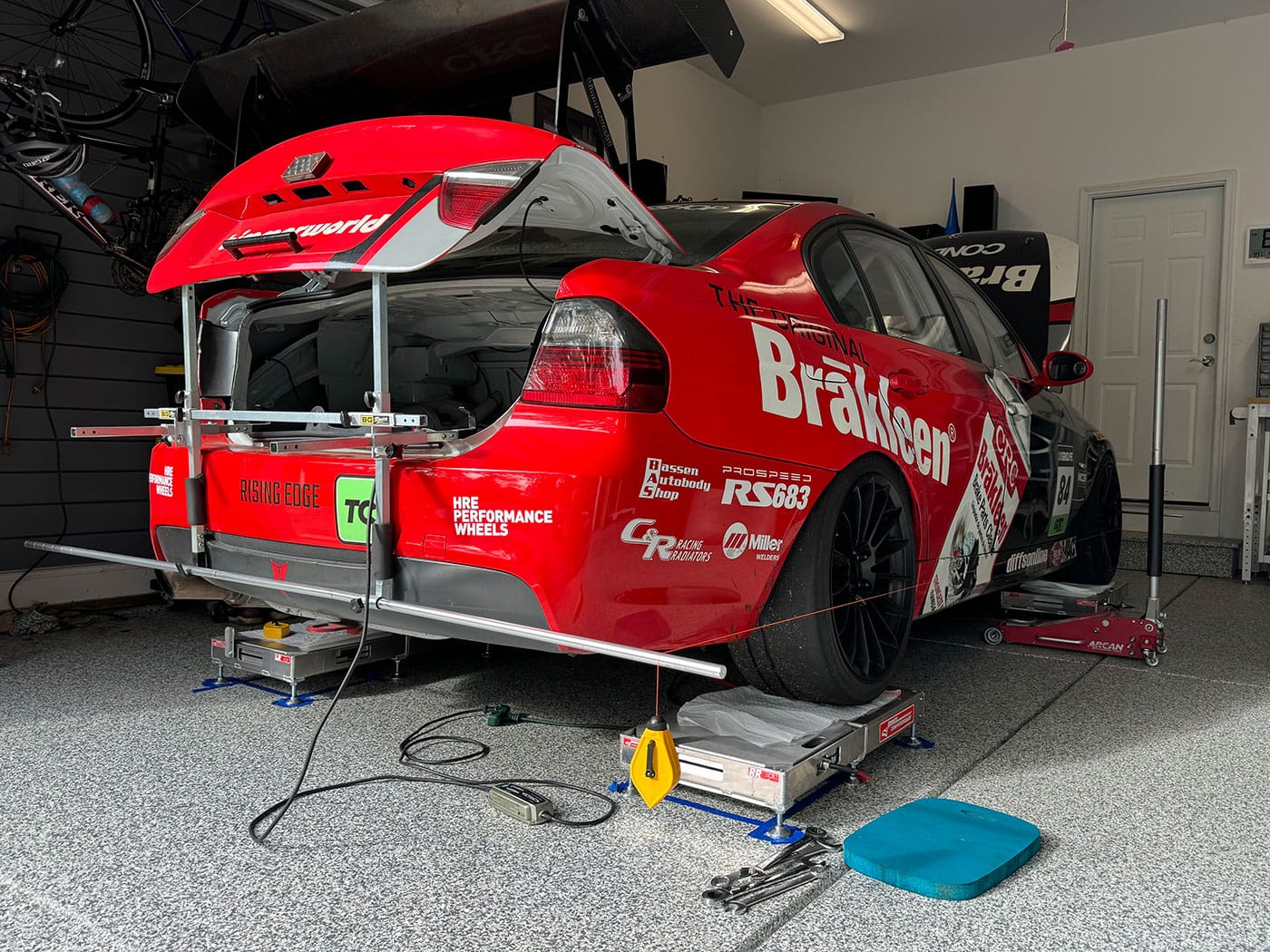

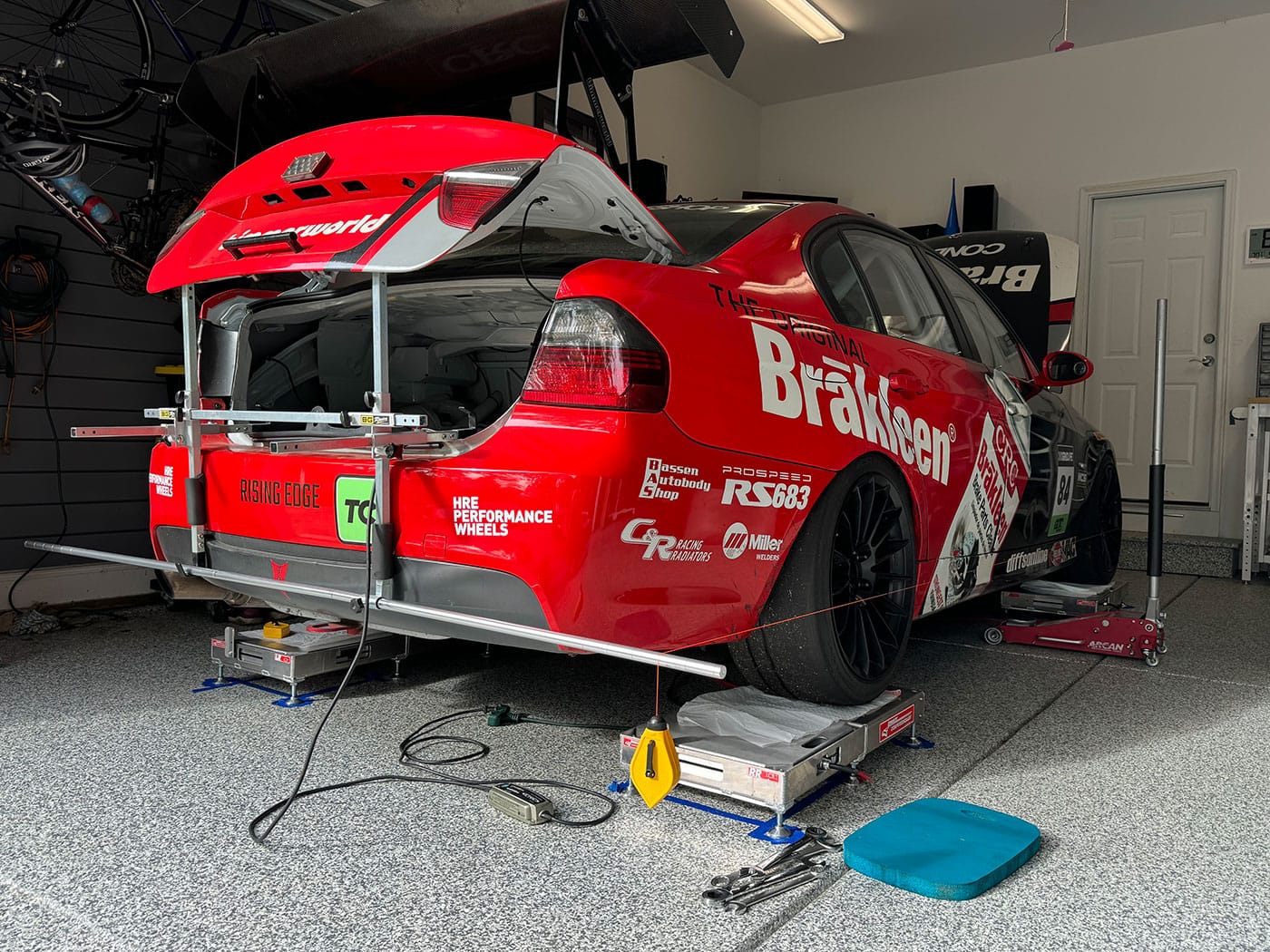

Since I don't have a lift in my garage, the process starts by marking the car's position with tape and carefully rolling it straight out of the garage. Next, I set up my scale leveling pads directly where the car sat. Because I can never get them in exactly the same place, and my garage floor is wildly uneven, I spend time making sure all four pads are level using a laser level.

Once that's done, I tape-mark all the feet of the leveling pads and move them out of the way. Then I carefully roll the car back into the garage, making sure it's positioned in the same spot as before.

Next, I jack up one side of the car at a time and slide the leveling pads under the wheels. On top of the leveling pads, I place several layers of thick garbage bags–they provide a slippery surface so the tires don't bind on the pads, which can bind the suspension and throw off alignment and weight numbers.

This process usually takes upwards of 2 hours, so my first night is already over!

The next night, I set up my B+G string alignment kit. It goes together quickly but requires a lot of fine-tuning to ensure it's perfectly square to the car. Otherwise, the readings it gives are not helpful!

Once the string kit is squared up, it's time to add ballast to the car equal to my weight, including my racing gear. This way, I don't have to be in the driver's seat to check the corner balance numbers.

Done? Not quite. The front and rear sway bars need to be disconnected so that any tension on the bars doesn't influence the corner balance numbers. Then, I pump out the fuel tank and add back the appropriate amount to ensure the fuel load is accurate.

Lastly, the tire pressures are set to my target "hot" track pressures.

Another two hours are gone, so night two is already over.

Depending on how far off or how many changes I am making to the alignment, that process can take another one to two nights, including rechecking and adjusting the corner balance. Each change to the alignment affects the corner balance and vice versa. Three or four rounds of back-and-forth changes are typical.

When I am happy with the numbers, I adjust the sway bar end links to reinstall them without any tension on the bars, then do a final recheck of the corner weights to ensure that reconnecting the bars didn't change the numbers.

Finally, it's time to remove the ballast, bring the car back down, disassemble the string kit, and put away all the scale parts and tools.

This process usually takes me 3-5 nights, and since I rarely work several nights in a row, it usually takes a week.

Of course, it could be done quicker, but I enjoy this kind of work's iterative, tinkering nature and don't like trying to rush through it. Late at night, I make more mistakes, so I try not to cram too much into one night lest I misread the tiny ticks of a millimeter ruler or get my imperial fractions wrong (what a pain).

It's now easier to see why a shop might charge $600-$1,200 for a corner balance and race alignment, right? Though I like doing this work, I don't think anybody would be willing to pay me what it would cost for me to do it.

Let's drive faster together