Author's Note: This kicks off a new series, Why I Like, wherein I'll share products, companies, events, and other things that I like, and why you should too. This week we are starting out with chassis-mount shifters. Next week we will have a companion article that is an in-depth buyer's guide for BMW chassis-mount shifters. The buyer's guide is the longest RISING EDGE article to date (by a long shot), so stay tuned for that!

What is a chassis-mount shifter?

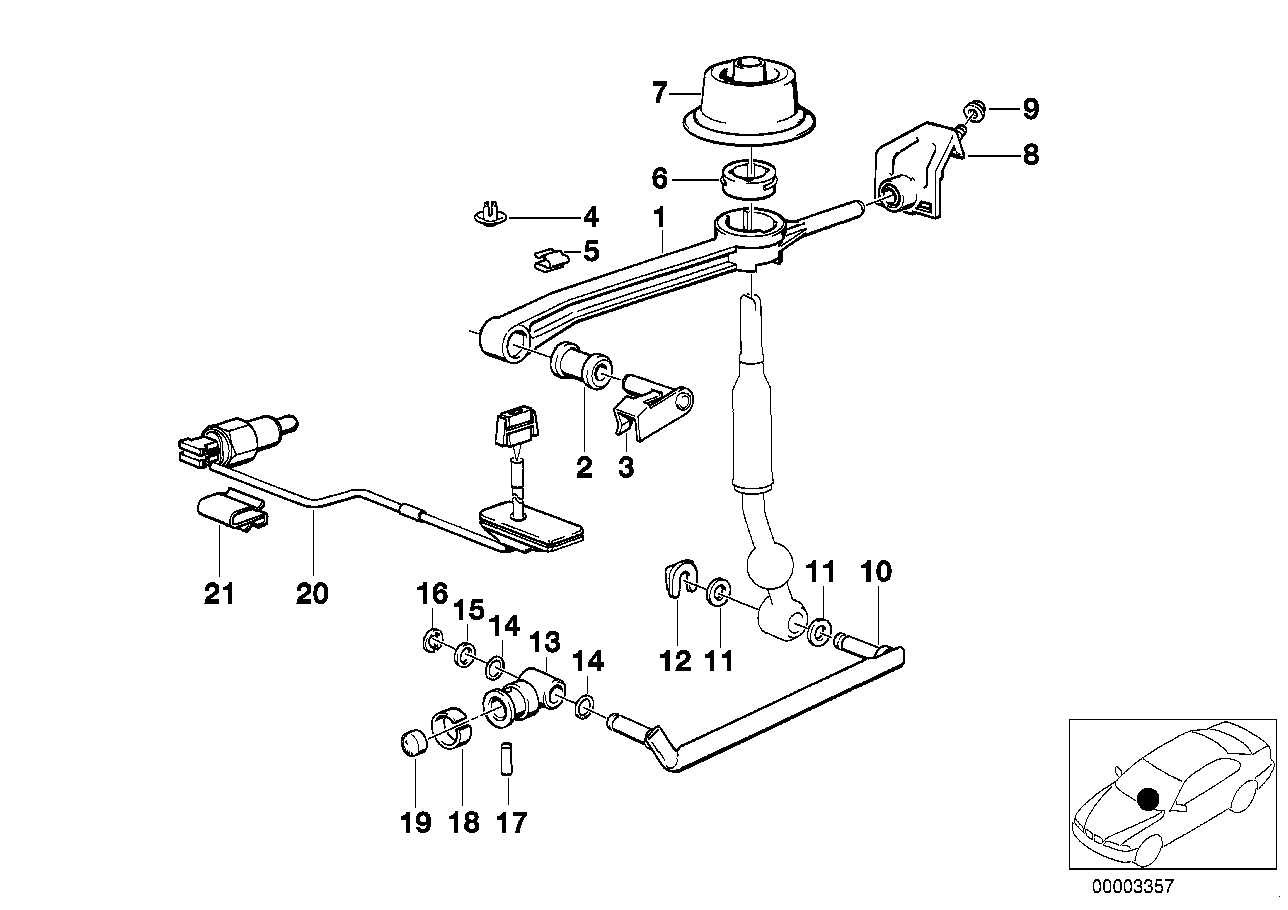

Most manual transmission BMWs feature a "shift carrier" assembly that sits within the transmission tunnel, connected at the front to the transmission itself, and at the back to the tunnel, with bushings at both ends.

This design is proven and durable, but it comes with some downsides, namely: flex, vagueness, and the inability to truly customize the shifter position in relation to the driver & steering wheel.

A chassis mount shifter removes the entire shift carrier assembly, instead opting for a mount/base that is attached directly to the transmission tunnel. This method does not allow the shifter to float with the driveline, and does not use any bushings or mounts that allow for flex. The shifter is thus solidly affixed to the chassis.

I'm not aware of the origins of chassis-mount shifters, but I do know that they were used as early as the 1980's on the BMW factory team E30 M3 race cars. They were even utilizing "DSSR" selector rods back then.

BMW's shifters were relatively simple aluminum plates, with a spherical bearing as the pivot, and a tall aluminum lever in the cabin. BMW opted to mount theirs inside the transmission tunnel, rather than on top, but by and large modern interpretations of the chassis-mount riff on BMW's original design, such as AKG's and Bimmerworld's offerings.

What are the benefits?

Chassis-mounting the shifter mechanism removes complexity from the shift carrier, and it does make the shifting action way more solid and direct-feeling. This isn't the only benefit, though.

The other key benefit of almost every chassis-mount shifter on the market is the change in geometry for the shift lever itself. They are much, much longer in both directions than OEM style shift levers. They are longer below the fulcrum, or pivot, of the shifter, which allows for much shorter throws between gears. They are also much longer above the fulcrum (inside the cabin), which allows for better positioning of the shifter in relation to the steering wheel.

The long shift lever also provides leverage and returns some of the knob travel lost to the shorter throws: if you paired an ultra short throw shifter with a low-sitting lever, the shifting effort and the miniscule travel of the lever would be impractical.

Lastly, many new chassis-mount shifter designs incorporate extra features, such as gear lockouts to prevent mis-shifts, multiple bearings for smooth, play-free operation, and adjustable geometry.

Who they are for

While chassis-mount shifters are generally marketed towards any manual transmission BMW owner, I personally think they are best relegated to track use, where you are always driving with a performance mindset. I've driven chassis-mounts on the street before, and when you are putting around town, their extra effort is too much to be comfortable or practical. If you really want one in a street car, I'd say fine if it's only a weekend warrior, but not if it's a daily driver.

Why I like chassis-mount shifters

I've personally owned 4 different types of chassis-mount shifters, and I've also driven several more. I've enjoyed them all on-track, and they've each had their pros and cons. We'll get into those in next weeks buyer's guide.

In my #74 TT6 E30, the IRP v3 shifter is honestly one of my favorite parts about the car. Being a track-only car, I was already running the stiff driveline bushings that you need to run with a chassis-mount shifter. The first chassis-mount that I had in that car was the AKG Stage II Racing shifter, which is similar to the BMW DTM shifter assemblies of the 80's. I didn't have much complaint with the AKG shifter, but once I saw the IRP shifter, I knew I had to give it a try.

The IRP v3 shifter is much more complex in comparison. The mount itself is somewhat of a turret, which mounts the fulcrum of the shifter above the transmission tunnel by a few inches. This keeps the selector rod more in line with the transmission's input shaft (versus sitting down lower and at more of an angle), which theoretically reduces shift effort. It has adjustable gear lockouts on both sides, which you can bypass by depressing the button at the top of the lever. It also has a bevy of needle and radial bearing throughout, ensuring smooth and friction-less function.

The gear lockouts were one of the key features that attracted me to the IRP v3 shifter. I've never money-shifted a car before, and I don't intend to. Typically you'd at least lockout reverse if your shifter allows it. With the ultra-short final drive ratio I run in my E30 (4.45), I knew I would never be using 1st and 2nd gear on the track, so I locked those out as well. On the other side you can lock out 5th gear, but I use 5th gear a lot with the short final drive, so I used the lockout adjustment to simply limit the right-side travel of the shifter throw. In other words, you can't move the shifter past the 5th gear gate, which would make engaging the gear difficult. With the adjustment, 5th gear always slides in easily and reliably, and when downshifting on-track, I know I can't accidentally engage 1st or 2nd.

The ergonomics of a tall shift lever really make a difference. Your hand is never far from the shift lever, allowing for a quick gear change, then returning the hand back to the steering wheel. Just check out one of my on-track videos to see:

To me, any negatives of a chassis-mount are outweighed by their benefits. All in all, I've been very happy with my experiences using chassis-mount shifters on the track, and expect to continue using them in future projects as well.

Have you used a chassis-mount shifter? What was your experience like? Sound off on our contact form and let's discuss!